REQUEST A DEMO

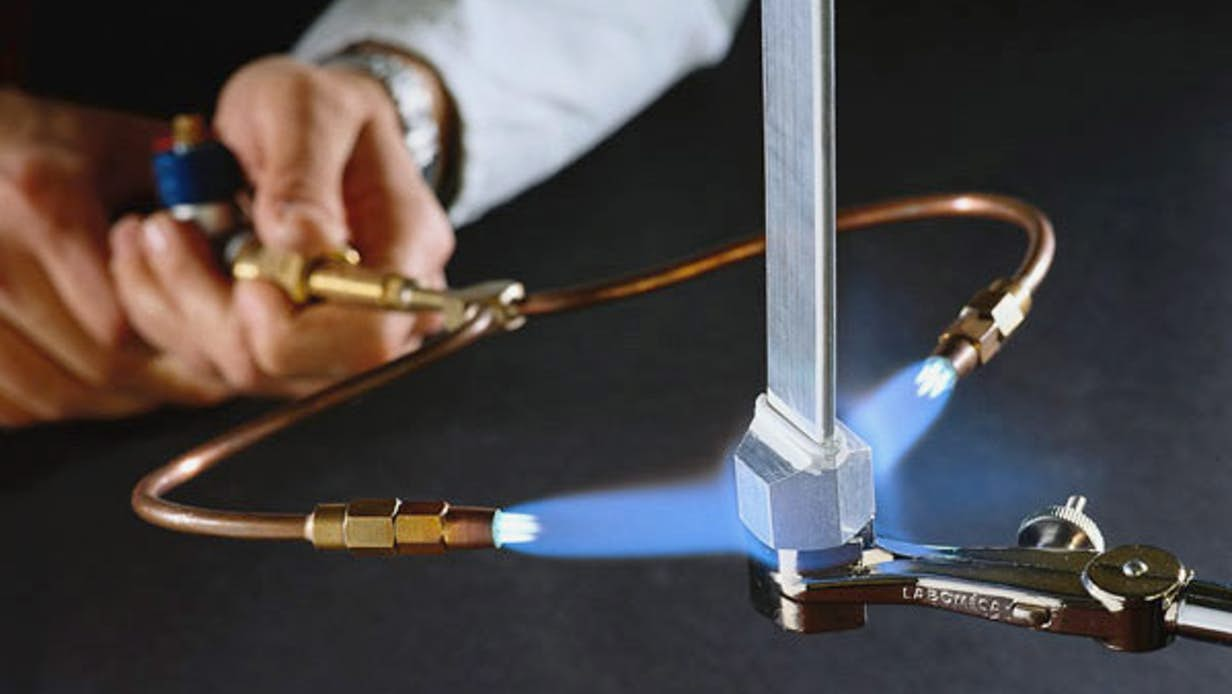

A New SAFER Flame From Water.

For Brazing, Acrylic Polishing and Jewellery Work

Safeflame was the product from the €1.8m EU Project to carry out research and development for a new and safer flame.

Download our 2020 brochure

The Safeflame unit is different from most of the “Flame from water” that are available in the market that utilises the HHO technology. Safeflame utilises the latest technology PEM cells which is much safer from the very common HHO systems.

About SafeFlame

Safeflame (UK) Limited was created to exploit the results from the project commercially. Safeflame is based in Frome, Somerset in the UK.

There is a range of Safeflame units in various sizes available to view and can be used to assess the size of the Safeflame unit required for the tasks the customer is hoping to achieve.

What is Safeflame?

The Safeflame unit is different from most of the “Flame from water” that are available in the market that utilises the HHO technology.

FIND OUT MORESomerset, BA11 2FQ

E : sales@safeflame-uk.com

T : +44 (0) 1373 466500 / 01373 487004